Design considerations PowerPoint templates and themes for Design considerations presentations ready for download - easily create stunning presentations slides within a. Tolerances for minimum radii as follows.

Design Consideration For Casting

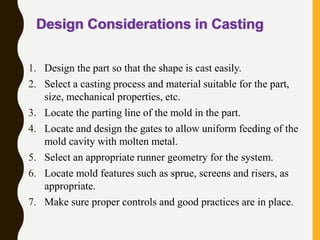

Locate and design the gates to allow uniform feeding of themold cavity with molten metal.

. Basic Requirements of Casting Processes Six basic steps of casting 1. Share Add to Flag Embed. Locate the parting line of the mould in the part.

Ken Youssefi Mechanical Engineering Dept SJSU 11 Design Consideration. General design principle for casting. Different Methods to design Riser in casting is discussed.

Investment casting include the use of a well located pattern straight parting line adequate draft and avoidance of undercuts generous radii and fillets. Design considerations of Castings - Summary. Casting Processes Tim Goldmann General Overview Caleb Hanson Molten Metal.

It is embedded in molding sand and suitable ramming of molding sand around the pattern is made. SJSU 10 Casting Defects and Design Consideration. Construction and operating costs The cost of construction can be minimized by adopting a layout that gives the shortest run of.

Suitable material for investment casting. It is very important for GATE mechanical exam. Cast components are stable rigid and strong compared with machined or forged parts.

Design Consideration In Casting-General tips For Casting Design. The development of a complete plant design involves consideration of many different topics. Design the part so that the shape is cast easily.

Complex parts which are otherwise difficult to machine are made by the casting process using sand mould. Complex parts which are difficult to machine are made by the casting process using send mould Size of the send casting can. Design Consideration In Casting.

We covered the creation of patterns and the setup of the mold and gating system. Since patterns are injection moulded a good practice must be followed for injection moulded parts. Design Consideration In Casting-General tips For Casting Design.

Presentations PPT KEY PDF logging in or signing up. Mold cavity is produced having the desired shape and size of the part Takes shrinkage into account Single-use or permanent mold 2. Suitable material for investment casting.

In the die casting design process metal flow is one of the most important considerations. A Always keep stressed areas of the part in compression b Round all external corners c Whenever possible the section thickness throughout should be held as uniform as possible dAvoidconcentration of metal at thejunctionas the same is likely to result in shrinkage cavity or a blow hole. This last step in the development process is the most.

Select a casting process and material suitable for the partsize mechanical properties etc3. Apps work but safari doesn t. Construction and operating costs.

Examples of cast components are machine tool beds and structures cylinder blocks of internal combustion engines pumps and gear box housings. Casting Processes Tim Goldmann General Overview Caleb Hanson Molten Metal Phillip Pinsonneault Mold Design Rey. 1 Riser Design Casting Definition.

Up to 24 cash back Design Considerations in Metal Casting Mold and Gating System Design Directional Solidification and Troubleshooting In the previous sections we discussed the fundamental aspects of manufacturing parts by metal casting. Thus it is a mould forming tool. E Avoid very thin.

Riser is defined as a reservoir for supplying molten metal to the casting cavity to compensate additional molten metal the liquid shrinkages taking place due to solidification. Other important factors include metal flow and porosity. When designing casting the most important consideration is the effects of shrinkage.

When designing casting the most important consideration is the effects of shrinkage during cooling. Omega speedmaster automatic 1997. Melting process Provides molten material at the proper temperature 3.

GENERAL DESIGN CONSIDERATIONS. Automation Automation of functionality and decisions. Create Survey Create Quiz Create Lead-form Get access to 100000 PowerPoint Templates For SlideServe Users - Browse Now.

DESIGN CONSIDERATIONS IN PATTERN MAKING PATTERN A pattern is a model or the replica of the object to be casted. The pattern is then withdrawn for generating cavity known as mold in molding sand. Design Considerations in Casting 1.

Now you do not need to roam here and there for design consideration in casting ppt links. Materials and Economics Design Considerations in Casting Design of the part Casting process and material Locate parting line Locate design gates Locate mold features such as sprue screens and risers Design Consideration of Cast Parts Corners angles section. Locate the parting line of the mold in the part.

Investment casting include the use of a well located pattern straight parting line adequate draft and avoidance of undercuts generous radii and fillets. Design principle of castings round all the external corners wherever possible section thickness should be uniform avoid concentration of metal at the center of the component no thin sections allowed shot blasts the possible parts. General design considerations Since patterns are injection moulded a good practice must be followed for injection moulded parts.

Rib or Wall Height Minimum Fillet Radii. Hip hop radio stations columbus ohio. Checkout this page to get all sort of ppt page links associated with design consideration in casting ppt.

Ppt Design Considerations Powerpoint Presentation Free Download Id 6931310

Design Consideration For Casting

Chapter 12 Metal Casting Design Materials And Economics Ppt Download

Design Consideration For Casting

Design Consideration For Casting

Chapter 12 Metal Casting Design Materials And Economics Ppt Download

0 comments

Post a Comment